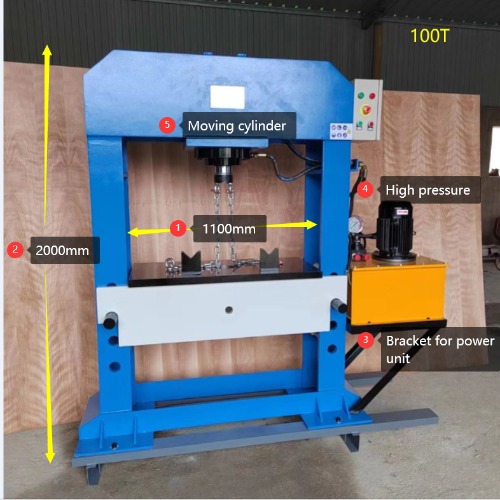

50T100T 150T 200T 250T 300T heavy duty gantry Electrical Hydraulic Shop Press H frame hydraulic press

Hydraulic shop press,Benchtop shop press,Heavy-duty shop press,Industrial shop press,Metalworking press,Workshop equipment,Pressing machine,Automotive press,H-frame press

"Advanced press system .Electromagnetic control system . With big pressure, stable and easy operation .

High efficiency , this is a perfec repairing equipment in salvage shop or other machine shops."

major functioni :

1. to align deformed parts

2. to dismount fastened parts

3. to rivet , cut or punch the rivets in crown wheel / pinion of rear axle.

|

型号

|

机身高度

|

机身密度

|

机身内宽

|

立柱密度

|

活塞行程

|

油路压力Mpa

|

PACKING SIZE&WEIGHT

|

|

DMY-II型电动压力机100T

|

1930mm

|

1100mm

|

780mm

|

262mm

|

300mm

|

31.5

|

|

|

DMY-II型电动压力机120T

|

2000mm

|

1120mm

|

800mm

|

290mm

|

300mm

|

31.5

|

|

|

DMY-II型电动压力机150T

|

2100mm

|

1150mm

|

830mm

|

324mm

|

300mm

|

31.5

|

1200*710*2100 910/990KG

|

|

DMY-II型电动压力机200T

|

|

|

|

|

|

|

|

-

Hydraulic press: Electrical shop presses often work using hydraulic power, which uses liquid to generate force.

-

Voltage: Since these presses are powered by electricity, they will have a specific voltage rating depending on the region they're used in and their intended application.

-

Capacity: The maximum amount of force that an electrical shop press can exert is measured in tons or pounds and will depend on its design.

-

Die set: To perform different types of pressing tasks, an electrical shop press may be equipped with a variety of die sets that allow it to conform to different shapes and sizes.

-

Safety features: Like any heavy machinery, electrical shop presses should come with a range of safety features such as emergency stops, overpressure protection, or guarding to prevent accidents or injury.

-

Industrial applications: Industrial settings like manufacturing plants, assembly lines, or repair shops are common environments where electrical shop presses might be used for tasks like forming metal parts, pressing bearings, or removing pins.

The Benefits of Electrical Shop Press

An electrical shop press is a powerful and versatile tool that can help you to perform a range of tasks quickly and efficiently. From compressing springs to bending metal, pressing bearings or removing and installing bushings, an electrical shop press is an essential piece of equipment for many industrial, manufacturing, and automotive applications.

Here are some of the key advantages of using an electrical shop press:

Increased Efficiency

An electrical shop press can increase your productivity and save you time by allowing you to accomplish more work in less time. The electric motor of the press provides consistent power, while the control system allows precise adjustments to be made to ensure accurate and efficient operation. This increased efficiency can lead to higher output levels, decreased downtime, and ultimately, improved profitability.

Improved Precision

Precision is key in many industries, and an electrical shop press offers impressive accuracy when it comes to controlling pressure and ensuring precise alignment of the components being pressed. Additionally, the electric motor ensures that the press can maintain a constant output pressure during the entire pressing process, which leads to reliable and high-quality results.

Time-Saving Features

Electrical shop presses often come with features that save you time during the pressing process. These include automatic shut-off valves, pre-set pressure settings, quick-change dies, and adjustable height settings. All these features make the pressing process faster and more hassle-free, resulting in greater efficiency and productivity.

Safety Features

Many electrical shop presses feature safety mechanisms designed to prevent injury during use. These may include protective shields, interlocking guards, and safety switches that prevent the press from starting unless all safety measures are in place. Some presses also have automated systems that reduce the risk of injury by minimizing the need for manual handling.

Versatility

Another advantage of electrical shop presses is their versatility. With the ability to apply a range of pressures, different dies and accessories available, they can accommodate a wide array of applications. Whether it’s pressing bearings or rivets, bending metal, straightening shafts, or removing and installing bushings – an electrical shop press can handle them all.

Overall, an electrical shop press can provide a range of benefits to those in need of high-quality and reliable pressing capabilities. The technology has come a long way in recent years, with many brands offering enhanced features to improve efficiency, safety, and accuracy. Investing in an electrical shop press can be a smart move for any business seeking to achieve greater productivity, save time and money, and deliver top